Enzyme Applications

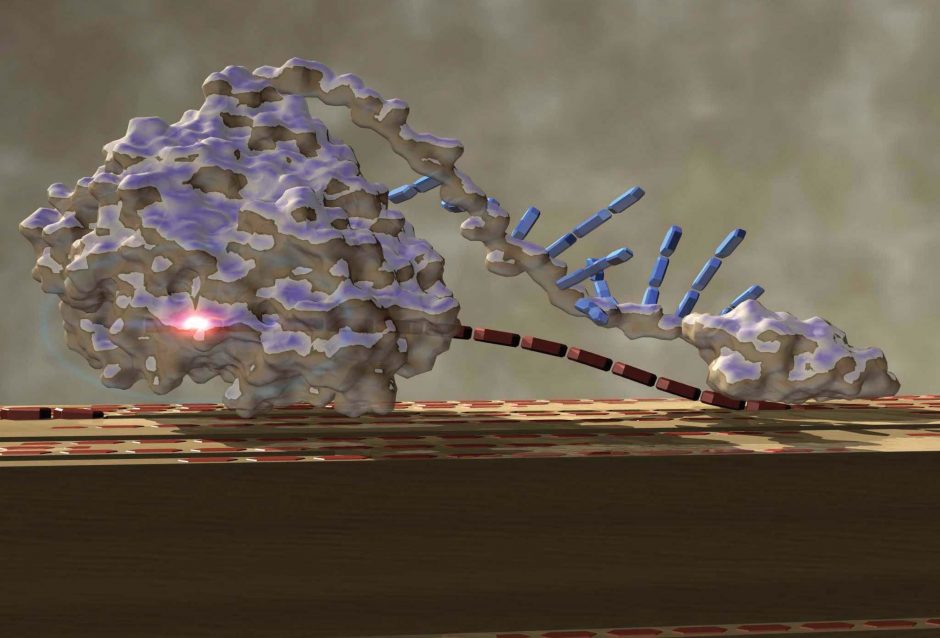

As well as breaking down the biomass into fermentable sugars, enzymes can be used at lower protein loadings and shorter reaction times, to modify the surface of cellulosic fibres for value-added applications.

In recent years, a number of fibrous cellulosic materials have been developed, including nanocrystalline cellulose, nano-fibrillated cellulose, and a wide range of intermediate fibrillated materials containing both nanoscale and microscale particles. These nano-cellulosic materials have shown considerable potential in various value-added areas such as nanocomposites, packaging, films, and paperboard applications. To date, most chemical processes, such as 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) oxidation, carboxymethylation, sulfonation, and cationization have proven to be relatively expensive and typically come with considerable environmental concerns. At the same time biological processes such as enzymatic treatments have attracted increased attention due to their potential to induce fibre modification, facilitating nano-fibrillation under more environmentally friendly reaction conditions.

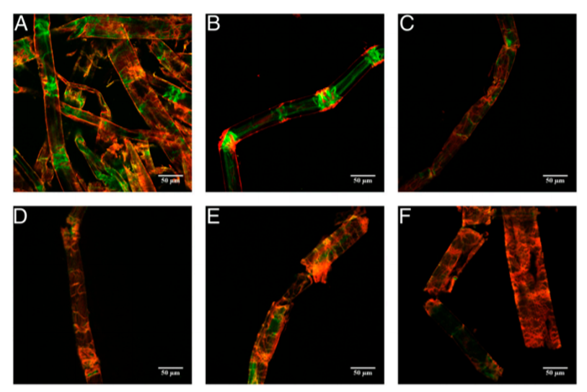

The FPB/B groups previous work has shown that endoglucanase treatment of highly refined micro/nano-fibrillated cellulose (MNFC) suspension resulted in a reduced aspect ratio of the cellulosic fibrils as well as disentanglement of inter-fibril interactions. This led to significant changes in the viscosity and shear-thinning properties of the MNFC, greatly enhancing desirable properties. Subsequent studies have shown that a variety of enzyme preparations, such as cellulase cocktail, xylanases and non-catalytic protein (swollenin) contributed to fibre swelling and changes of fibre morphology. These enzyme-mediated changes all enhance the fibrillation process.

As well as improving the properties of biomaterial our FPB/B group continues to use/assess enzymes for their ability to produce fuels and chemicals from biomass. High-yield pulps, such as thermomechanical pulp (TMP) and chemi-thermomechanical pulp (CTMP) typically have the advantage of lower cost, less biomass loss, and reduced environmental pollution when compared to delignified chemical pulps. Therefore, rather than using delignified substrates, our recent projects are focused on utilizing lignin-containing substrates such as softwood mechanical pulps as the feedstock for value-added applications. Promising results have been found when using cellulase cocktails, endoglucases and xylanases to facilitate the delamination and defibrillation of fibres during the fibrillation process, despite the presence of lignin, which contributed to the production of lignin-containing cellulose nanofibrils (LCNFs).